|

|||||

EM Update | Vol. 8, Issue 19 | Oct. 17, 2016

|

|||||

|

|||||

EM’s Mark Whitney Reflects on DOE Tenure

How would you compare EM today to when you came to headquarters?

What are the main things you’re most proud of during your tenure in EM?

What do you think will be EM’s next major near-term accomplishment?

Now, is there something you wish you could go back and do over or do differently?

What words of advice would you give to your successor?

What can you tell us about your future plans? What are you most looking forward to?

Twenty Years of Preparations to Culminate in Plutonium Finishing Plant Demolition

Demolition

will progress from the Plutonium Reclamation Facility (green) to the

Americium Recovery Room (red) during the remainder of 2016. Demolition

of the main processing facility (blue) and the fan house and ventilation

stack (orange) will begin in spring 2017.

RICHLAND, Wash. – Demolition of the Hanford Site’s Plutonium Finishing Plant (PFP) is scheduled to begin within weeks, capping years of challenging preparatory work.

EM’s Richland Operations Office

and contractor CH2M HILL Plateau Remediation Company (CH2M) will

conduct demolition slowly and methodically, with numerous controls and

extensive monitoring in place to ensure employee and environmental

safety.

“Today, we’re near the end of a 20-year remediation project to prepare

the facility for safe demolition,” EM Federal Project Director Tom

Teynor said. “The start of its demolition will represent a huge step

forward for the Department, plant workers, the community, and

stakeholders, as well as the agencies we’ve worked with to get to this

point.”

Crews open a portion of the PRF roof to remove pre-staged glove boxes inside.

Crews recently opened portions of the Plutonium Reclamation Facility

(PRF) roof for a crane to remove eight glove boxes from the upper three

floors (see a time lapse video here).

Crews had already cleaned, decontaminated and prepared the glove boxes

for removal. Heavy equipment will demolish PRF after those hazards are

removed.

“We will move forward through demolition with our continued focus on

safety and each other, our continued cooperation, our teamwork and our

skillful approach to every task,” said Tom Bratvold, CH2M’s vice

president of the PFP Closure Project. “If we aren’t sure we can do it

safely, we won’t do it.”

Glove boxes will be removed from PRF and packaged for off-site disposal.

PRF is the first of four main PFP facilities to be demolished. Next is the Americium Recovery Facility, nicknamed the “McCluskey Room”

after a 1976 explosion that severely injured Harold McCluskey, who was

working inside. Using personal protective equipment, CH2M employees have

already prepared that building for demolition.

Demolition of the main processing and ventilation facilities is

expected to begin in early 2017. Crews have prepared the main building,

which is the largest of the four, by removing (or prepared to remove

during demolition) about 75 percent of contaminated process vacuum

piping and 65 percent of the contaminated ventilation duct. Workers are

removing asbestos, contaminated piping and filter boxes from the

ventilation building.

All demolition is scheduled for completion in summer 2017.

West Valley Site Prepares for Vitrification Facility Demolition in 2017

Workers verify deactivation progress in the vitrification cell.

WEST VALLEY, N.Y. – EM’s West Valley Demonstration Project

has completed 95 percent of deactivation activities at the

Vitrification Facility, preparing for its scheduled demolition in spring

2017, several months ahead of schedule.

Workers safely and compliantly removed all major equipment, cleaned

and sealed interior surfaces, disconnected all utilities and connections

with adjoining structures and obtained characterization data to plan

for demolition and waste disposal.

Demolition will produce approximately 6,500 tons of material requiring

transport for disposal. EM and contractor CH2M HILL BWXT West Valley

will conduct the demolition under the protocols used for the teardown of

the site’s once-contaminated 01-14 Building in 2013.

A cutaway drawing shows the internal workings of the Vitrification Facility.

Operating from 1996 to 2002, the Vitrification Facility produced 275

stainless steel canisters from solidifying 600,000 gallons of liquid

high-level waste and sludge generated from spent nuclear fuel

reprocessing. The facility is made up of a vitrification cell, which

housed all major radioactive process equipment, operating aisles and

working areas, and auxiliary buildings.

Standing 50 feet tall with walls and a roof up to 4 feet thick, the

11,000-square-foot concrete Vitrification Facility is reinforced with

structural steel and sided with sheet steel. Demolition workers will use

heavy equipment to size-reduce the waste and load it into containers

before shipping it to an off-site licensed disposal facility.

All activities will be conducted in accordance with state, federal and

regulatory requirements. Workers placed 16 ambient air monitoring

stations at locations outside the site boundary and will install

real-time air monitors around the demolition area to monitor for

potential airborne contamination releases.

An

aerial view of the West Valley Demonstration Project. The Vitrification

Facility’s deactivation activities are 95 percent complete and the Main

Plant Process Building’s deactivation activities are 56 percent

complete.

WVDP took special precautions to protect the workers, public and

environment from radiological and hazardous constituents prior to

demolition and to ensure safe handling of building debris, including:

Proposal to Control Tank Vapors Wins ORP’s Grand Challenge

Mark

Edgren, ORP chief of staff, left, presents Larry Shaffer and Clinton

Summers with a plaque announcing their Grand Challenge-winning proposal.

The two were part of a four-person team whose proposal aims to destroy

organic bearing compounds and remove mercury by installing special

skid-mounted treatment units to the vent pipes of Hanford tanks.

RICHLAND, Wash. –

A proposal to destroy organic bearing compounds and remove mercury by

installing special skid-mounted treatment units to the vent pipes of

tanks in Hanford’s tank farms was recently named the winner of the 2016

Grand Challenge.

Participants in the annual competition, now in its fourth year, propose and present creative ideas that can make a significant difference in the safety, quality, schedule and cost of EM’s Office of River Protection (ORP) mission. Judges then evaluate and select ideas for potential implementation.

The target cost savings for each Grand Challenge proposal is over $250 million.

A four-member team made up of Joe Enneking, Larry Shaffer, Clinton

Summers and Paul Kovach of the Columbus, Ohio-based NUCON International,

Inc. won with their proposal titled “Control of Vapors from Hanford

Storage Tanks.”

Their proposal would require about $1 million to produce and test a

prototype, but could save ORP up to $20 million a year. That could mean

more than $250 million as tank farms activities are anticipated through

at least 2040.

Grand Challenge judges reviewed 34 submissions from 20 organizations

and partnerships, and selected 10 finalists who presented their

proposals in September. Judges looked at factors such as technical

viability and risks, whether proposals were achievable within a

timeframe to meet mission needs, whether they were executable with

existing safety basis requirements, cost avoidance, cost savings, and

process efficiencies.

ORP will study about 18 of the proposals for potential implementation,

according to Ricky Bang, an ORP facility representative and Grand

Challenge advisor.

If only the top 10 were implemented, it could save taxpayers a

significant amount of money, said Elaine Diaz, ORP’s chief engineer and

Grand Challenge lead advisor.

“Grand Challenge is about getting the job done better, safer and

sooner, and spending less of our tax dollars in the process. We all want

that,” she said. “By tapping into great ideas from industry, academia,

our network of national labs, and our own employees, we can make a

significant difference.”

Employees from DOE and its contractors, national laboratories, universities and corporations entered submissions.

“I think this year was good because a variety of organizations

participated,” said Bang. “I would say we got an improvement over last

year through the increased collaboration between organizations. That

resulted in better, more complete ideas that we can study.”

The second-place proposal was “Optimization of Sodium Concentration in

Direct-Feed, Low-Activity Waste Feed,” by Sahid Smith, Wendell

Wrzesinski and Ben Harp, all from ORP.

The third-place proposal was “Hanford Waste Storage Capacity

Management: Double-Shell Tank Life Extensions Supported by Forensics,

Diagnostics, and Prognostics,” by Kayte Denslow, Kenneth Johnson, and

Michael Rinker of the Pacific Northwest National Laboratory; Kayle

Boomer, Theodore Venetz and Jason Gunter of contractor Washington River

Protection Solutions; and Dennis Washenfelder of AEM Consulting.

EM Marks Groundwater Characterization Milestone at Nevada Site

NNSS

Scientist Jenny Chapman (foreground) discusses groundwater

characterization at Frenchman Flat with a resident of Amargosa Valley,

Nev. at the 2016 NNSS Groundwater Open House.

LAS VEGAS – EM recently achieved a groundwater characterization milestone at the Nevada National Security Site (NNSS) when

the State of Nevada Division of Environmental Protection approved

transitioning a groundwater investigation area to long-term monitoring.

That’s the end goal of a strategy outlined in the Federal Facility

Agreement and Consent Order for five groundwater investigation areas at

NNSS. Frenchman Flat, the site of 10 underground nuclear tests between

1965 and 1971, is the first to enter this important final stage.

The Frenchman Flat success follows over 20 years of hard work and

continuous study by multiple organizations, including two external peer

reviews. In that time, multiple groundwater characterization wells were

drilled, three-dimensional computer models were developed and refined

and boundaries for restricted access were established.

“The NNSS is one of the most studied locations in the world, and this

achievement is a testament to the teamwork between all organizations

involved,” said Bill Wilborn, manager of NNSS groundwater

characterization for EM.

The underground nuclear tests at Frenchman Flat provided valuable data

in a few spectacular seconds. In the decades to follow, NNSS scientists

worked to understand the effects of those tests on the site’s

groundwater. Their studies confirmed that the contamination from nuclear

testing in groundwater at Frenchman Flat poses no risk to the public.

While entering long-term monitoring signifies a thorough understanding

of the groundwater flow system, routine monitoring at Frenchman Flat

will continue, and results will continue to be reported annually in a publicly-released report.

Scientists prepared a report detailing

the Frenchman Flat studies. Their findings include that contaminated

groundwater is not expected to leave the Frenchman Flat basin, and that

radionuclides in the groundwater will travel less than a mile in 1,000

years.

“The groundwater flow system and potential for contaminant movement is

well understood, to the point that protection of the public is

ensured,” said Wilborn.

Transitioning Frenchman Flat to long-term monitoring provided NNSS

scientists and staff with an invaluable experience for understanding the

necessary balance of modeling, monitoring and restricted access

protective of the public and the environment. It also sets the stage for

other NNSS groundwater investigation areas.

“Although the regulatory strategy is the same, each will have unique

challenges due to the varying subsurface environments,” said Wilborn.

NNSS groundwater studies will continue with the goal of transitioning all areas of the NNSS to long-term monitoring.

Click here to learn more about groundwater characterization at the NNSS.

DOE Representatives Mark 60 Years of IAEA General Conference

EM

Assistant Secretary Monica Regalbuto (front row, second from right), at

a recent U.S.-hosted reception at the Palais Ferstel in Vienna

celebrating the 60th anniversary of the International Atomic Energy Agency’s

(IAEA) General Conference. Also pictured, front row, left to right, are

Ben McRae with the DOE Office of General Counsel, IAEA Director General

Yukiya Amano, and Farah Benahmed, NE; back row, left to right, Michelle

Scott, NE, NE Acting Assistant Secretary John Kotek, Andrew Richards,

NE, and Aleshia Duncan, Organization for Economic Cooperation and

Development Nuclear Energy Agency.

Paducah Site Improves Groundwater Treatment

Operators drill wells during the first phase of the project to further optimize groundwater treatment.

PADUCAH, Ky. – Nine new monitoring wells have been installed in the northeast section of EM’s Paducah Site, representing the first phase of a project to enhance groundwater treatment.

Data from the new wells will support the project’s next phase, which

includes installing an additional 13 monitoring wells, two extraction

wells, and a new treatment facility to augment the existing

pump-and-treat unit. The next phase begins when samples from the nine

new monitoring wells are assessed.

A horseshoe-shaped area of contaminated groundwater plumes containing

trichloroethene (TCE) extends under the site. TCE was used to clean

equipment when the gaseous diffusion plant operated. The chemical’s use

was discontinued in the early 1990s.

Two pump-and-treat operations reduced the size of the plumes’

high-concentration portion. More than 3.6 billion gallons of water were

treated and more than 4,200 gallons of contamination were removed from

the groundwater.

“The optimization project is another positive step in containing and

controlling the groundwater contamination at the Paducah Site,” said

Dave Dollins, project manager with EM’s Portsmouth/Paducah Project Office (PPPO).

Fluor Federal Services, as EM’s prime contractor for the Paducah Deactivation Project, is setting up the new systems.

“The first phase of installing the new monitoring wells is a major

undertaking and key to the successful outcome of the optimization,”

Fluor Paducah Deactivation Project Environmental Management Director

Myrna Redfield said.

Like EM on Facebook:Moab Project Hosts International Meeting on Uranium Mining and Remediation

The visitors pose for a group photo on the disposal cell cover at the Crescent Junction site.

GRAND JUNCTION, Colo. – More than 40 people from around the world met recently for the International Atomic Energy Agency (IAEA) meeting to share lessons learned and address environmental aspects of uranium mining and remediation projects.

EM’s Moab Uranium Mill Tailings Remedial Action Project hosted the meeting and provided a tour of EM’s project sites in Moab, Utah to the

environmental and project managers, operators, researchers and

regulators from the U.S. and 13 other countries in attendance.

The meeting at Colorado Mesa University in Grand Junction highlighted

the local academic institution, which offers degrees in environmental

science and geology and is expanding its engineering programs.

University President Tim Foster welcomed the group.

Dr. Peter Woods, IAEA’s organizer, considered the meeting a success.

“I have had very positive feedback from participants,” he said. “With

26 technical talks involving over 40 participants from 13 IAEA Member

States, the meeting was diverse and well attended. This shows the wide

interest in the topic of the remediation of former uranium mining and

milling sites.”

The participants toured the site where 16 million tons of mill

tailings, the remains from the former uranium-ore processing mill, are

being excavated, conditioned and placed in metal containers for shipment

by rail to Crescent Junction for permanent disposal.

EM

Federal Project Director Donald Metzler (orange vest) discusses mill

tailings removal and conditioning processes during the Moab Site tour.

EM Federal Project Director Donald Metzler and Moab Technical

Assistance Contractor Senior Program Manager Joe Ritchey described the

regional geology and history to the tour participants as they traveled

by bus 100 miles from Grand Junction to Moab.

Longtime Moab Mayor Dave Sakrison kicked off the tour in Moab,

emphasizing the importance of working with the local community to gain

support for cleanup projects.

Metzler, who gave an overview of the Moab project to the tour

participants, has a long history of participation in IAEA meetings,

especially with the Uranium Mining and Remediation Exchange Group, which

was adopted under the IAEA in 2012.

“Being the host for one of these meetings, which I feel benefits our

project as much as any of the others discussed, has been on my bucket

list for many years. I’m glad we were able to show other parts of the

world the important work that we’re doing to take care of our legacy

waste,” Metzler said.

Woods expressed his appreciation for the tour.

“The field trip to the Moab project, including the disposal cell site

at Crescent Junction, was a highlight for many,” Woods said. “I thank

the DOE team for their great cooperation, organization and hospitality.”

New Idaho Site Robotic Technology Adds Muscle, Enhances Safety

Waste awaiting retrieval at AMWTP’s Transuranic Storage Area Retrieval Enclosure.

IDAHO FALLS, Idaho – Thanks to new robotic gear, EM’s Idaho Site is better armed to safely and compliantly handle the cleanup complex’s transuranic radioactive waste.

A safe, reliable and accessible tool for opening waste drums and boxes, the new robotic arm began operating this month at the Advanced Mixed Waste Treatment Project’s (AMWTP) Treatment Facility.

It’s the first of two arms being installed, replacing the facility’s

original robotic arms used to examine, sort and treat much of the legacy

waste at AMWTP in the past 12 years.

The new arms are intended to create a safer work environment, enhance

productivity and reduce maintenance costs by an estimated 80 percent. In

2015, maintenance personnel entered the facility’s highly contaminated

boxlines more than 500 times, each time at a cost of at least $3,600.

Crews also report the new arm is easier on their hands and wrists.

Updating AMWTP’s capabilities is timely as retrieval crews remove the

last of the waste containers stored at the site for nearly a half

century.

The crews currently deal with the most challenging degraded

containers. Experience from retrieving more than 64,000 cubic meters of

stored waste has helped them prepare to remove the last 550 cubic

meters.

In preparing for the final retrieval work, crews reported the need for

equipment for increased ventilation to reduce potential contamination

levels. Their suggestions led EM to develop a system of pulleys and

rails to move a newly designed ventilation hood and hose inside the

inner contamination enclosure, a large, movable tent for seriously

degraded drums and boxes. The system increases air flow and prevents the

crews from sustaining strains and sprains caused by moving the

ventilation equipment.

AMWTP’s retrieval operations are scheduled for completion by May 2017.

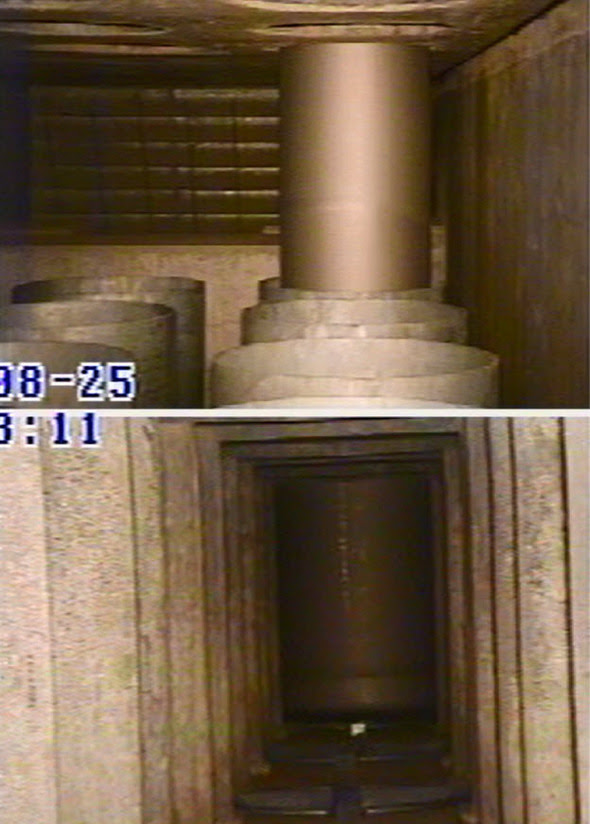

Savannah River Site Begins Double-Stacking Waste Canisters

This

graphic shows the innovative concept for the canister double-stack

project. Each current canister position is being modified to accommodate

two canisters per existing slot.

AIKEN, S.C. – EM began double-stacking radioactive canisters recently at the Savannah River Site (SRS), part of an innovative effort to increase onsite interim storage capacity of glassified high-level waste.

A shielded canister transporter is used to stack two canisters in the

Glass Waste Storage Building (GWSB) 1 at the Defense Waste Processing

Facility (DWPF). Savannah River Remediation, the SRS liquid waste

contractor, is conducting the process.

To modify the canister positions to accommodate two, 10-foot tall

canisters, SRS employees developed a remote cutting tool to remove the

existing canister support crossbar.

SRR engineers created the tool for less than $120,000 — approximately 25 percent less expensive than commercial ones.

DOE-Savannah River Assistant Manager for Waste Disposition Jim Folk

said the project is a win for SRS and for saving taxpayer money.

“At DOE, we want to see safe, creative solutions to solve issues,”

Folk said. “Finding this new method for canister storage is a

game-changer in terms of finding new storage space that will save tens

of millions of dollars.”

The

first two canisters stacked on top of each other. In the bottom photo,

the first canister sits on the crossbar. In the top photo, the second

canister is positioned on top of the first canister.

SRS has removed more than 250 of 2,254 crossbars, and 150 of those

have been prepared for double-stacking, including installation of a new

support plate and shield plugs. The project will continue to modify

canister positions for up to eight years, as needed.

Double-stacking increases the storage capacity in GWSB 1 from 2,254

slots to 4,508 slots, creating adequate safe interim canister storage

until at least fiscal 2029 and postponing the expense of another storage

facility estimated to cost $74 million.

The radioactive canisters contain vitrified waste produced at DWPF.

High-level waste from SRS waste tanks is received at DWPF, mixed with a

borosilicate glass and heated to create a molten glass, which hardens

when poured inside the stainless steel canister. The canister is

temporarily sealed, the exterior is decontaminated, and a weld seals the

canister prior to storage transport.

The canisters are destined for a future federal repository, but pose

no technical or radiological issues staying at SRS in this interim

double-stack storage arrangement, according to engineering studies.

Hanford Site Technology Completes Cleanup to Protect Groundwater

Equipment used in soil vapor extraction was used to reduce the level of carbon tetrachloride on the Hanford Site.

RICHLAND, Wash. –

Regulators have approved the completion of a cleanup project on the

Hanford Site that began nearly 25 years ago that successfully removed

nearly 90 tons of deep-soil contamination and reduced groundwater risk

using a remediation technology known as soil vapor extraction.

EM’s Richland Operations Office

(RL) and contractor CH2M HILL Plateau Remediation Company (CH2M)

employed the technology to clear contamination by the chemical carbon

tetrachloride, which was used in Cold War plutonium processing

operations. It spread to an area approximately three-fourths of a square

mile and approximately 200 feet in the ground in the 200 West Area.

“This is a major accomplishment and success in our primary goal of

protecting the groundwater, which also protects the Columbia River,”

said Michael Cline, director of the RL soil and groundwater division.

Nearly 90 tons of contamination has been removed since workers began

operating the soil vapor extraction system to clean up carbon

tetrachloride in 1992.

The system was shut down in 2012 after carbon tetrachloride levels

were below final cleanup levels. A study performed from 2012 through

2015 showed the chemical was sufficiently removed, leaving no continuing

source.

The U.S. Environmental Protection Agency approved a soil vapor

extraction action report in August, completing all actions associated

with removal of carbon tetrachloride in that area.

“Our team of experts worked to track the contamination and maintain

the systems to assure removal of the largest amount of contamination

possible,” said Karen Wiemelt, vice president of CH2M’s Soil and

Groundwater Remediation Project. “Due to the expertise of our team and

other support groups we achieved the legal cleanup level for carbon

tetrachloride and were able to permanently end soil vapor extraction

operations.”

Removal of contamination from the vadose zone was crucial because it

reduced the amount of contamination reaching the groundwater.

Progress Moves West Valley Closer to Finishing Canister Relocation Project

Workers place a vertical storage cask liner on a construction pad.

WEST VALLEY, N.Y. – EM’s West Valley Demonstration Project (WVDP) is about 70 percent complete toward relocating all high-level waste canisters from a building to be demolished.

The site’s High-Level Waste Relocation Project has safety relocated

195 of the 278 canisters and is on track to move the rest of them to an

interim dry storage facility before the end of 2016, nearly one year

ahead of schedule.

The canisters must be moved from a former chemical processing cell in

the Main Plant Process Building before WVDP and contractor CH2M HILL

BWXT West Valley can demolish that building and the Vitrification

Facility.

The relocation project, which began in November 2015, marked the first

time vitrified high-level waste was relocated for onsite interim

storage in the U.S.

The canisters are loaded into vertical storage casks. Nearly 40 casks,

each weighing about 88 tons, have been moved about a half mile away to

the onsite interim storage pad for eventual disposal offsite.

NAC International, a U.S. supplier of dry storage technology and

services to the nuclear industry, constructed all 56 casks for the

project. With a design life of at least 50 years, each cask was built

onsite, constructed of 20-inch-thick reinforced concrete and containing

4-inch-thick stainless steel liners. Their design is based on spent

nuclear fuel dry cask storage systems used throughout the world, with

modifications for long-term storage of vitrified high-level waste.

The company previously developed 10 major Nuclear Regulatory

Commission (NRC)-licensed systems and the first storage and transport

canister-based system fully approved by the NRC.

The NAC team, including subcontractors NAES Constructors and local

craft, Petersen Industries and Lift-Systems, partnered to provide WVDP’s

solutions for interim storage and future shipment of the high-level

waste for disposal.

Watch this video of workers constructing the casks and learn more about the project.

Hanford Site Technology Completes Cleanup to Protect Groundwater

Equipment used in soil vapor extraction was used to reduce the level of carbon tetrachloride on the Hanford Site.

RICHLAND, Wash. –

Regulators have approved the completion of a cleanup project on the

Hanford Site that began nearly 25 years ago that successfully removed

nearly 90 tons of deep-soil contamination and reduced groundwater risk

using a remediation technology known as soil vapor extraction.

EM’s Richland Operations Office

(RL) and contractor CH2M HILL Plateau Remediation Company (CH2M)

employed the technology to clear contamination by the chemical carbon

tetrachloride, which was used in Cold War plutonium processing

operations. It spread to an area approximately three-fourths of a square

mile and approximately 200 feet in the ground in the 200 West Area.

“This is a major accomplishment and success in our primary goal of

protecting the groundwater, which also protects the Columbia River,”

said Michael Cline, director of the RL soil and groundwater division.

Nearly 90 tons of contamination has been removed since workers began

operating the soil vapor extraction system to clean up carbon

tetrachloride in 1992.

The system was shut down in 2012 after carbon tetrachloride levels

were below final cleanup levels. A study performed from 2012 through

2015 showed the chemical was sufficiently removed, leaving no continuing

source.

The U.S. Environmental Protection Agency approved a soil vapor

extraction action report in August, completing all actions associated

with removal of carbon tetrachloride in that area.

“Our team of experts worked to track the contamination and maintain

the systems to assure removal of the largest amount of contamination

possible,” said Karen Wiemelt, vice president of CH2M’s Soil and

Groundwater Remediation Project. “Due to the expertise of our team and

other support groups we achieved the legal cleanup level for carbon

tetrachloride and were able to permanently end soil vapor extraction

operations.”

Removal of contamination from the vadose zone was crucial because it

reduced the amount of contamination reaching the groundwater.

| |||||

Michele Kearney's Nuclear Wire

Major Energy and Environmental News and Commentary affecting the Nuclear Industry.

Monday, October 17, 2016

EM Update | Vol. 8, Issue 19 | Oct. 17, 2016

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment