Dry Cask 101 – Radiation Shielding

Posted by on June 16, 2016

Drew Barto

Senior Nuclear Engineer

We’ve

talked before about how the uranium in nuclear fuel undergoes fission

during reactor operations. The fission process turns uranium into a

number of other elements, many of which are radioactive. These elements

continue to produce large amounts of radiation even when the fuel is no

longer supporting a chain reaction in the reactor. So shielding is

necessary to block this radiation, and protect workers and the public.

We’ve

talked before about how the uranium in nuclear fuel undergoes fission

during reactor operations. The fission process turns uranium into a

number of other elements, many of which are radioactive. These elements

continue to produce large amounts of radiation even when the fuel is no

longer supporting a chain reaction in the reactor. So shielding is

necessary to block this radiation, and protect workers and the public.

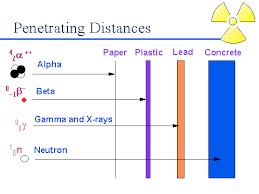

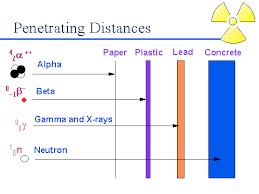

As we discussed in an earlier blog post, the four major types of radiation differ in mass, energy, and how deeply they penetrate people and objects. Alpha radiation—particles consisting of two protons and two neutrons—are the heaviest type. Beta particles—free electrons—have a small mass and a negative charge. Neither alpha nor beta particles will move outside the fuel itself.

But

spent fuel also emits neutron radiation (particles from the nucleus

that have no charge) and gamma radiation (a type of electromagnetic ray

that carries a lot of energy). Both neutron and gamma radiation are

highly penetrating and require shielding.

But

spent fuel also emits neutron radiation (particles from the nucleus

that have no charge) and gamma radiation (a type of electromagnetic ray

that carries a lot of energy). Both neutron and gamma radiation are

highly penetrating and require shielding.

Shielding is a key function that dry storage casks perform, but the two main types of dry storage casks are configured in slightly different ways.

For welded, canister-based systems, shielding is provided by a thick (three feet or more) steel-reinforced concrete vault that surrounds an inner steel canister. The thick concrete shields both neutron and gamma radiation, and may be oriented either as an upright cylinder or a horizontal building.

In bolted cask systems, there is no inner canister. Bolted casks have thick steel shells, sometimes with several inches of lead gamma shielding inside. They have a neutron shield on the outside consisting of low-density plastic material, typically mixed with boron to absorb neutrons.

The

NRC reviews spent fuel dry cask storage designs to ensure they meet

our limits on radiation doses beyond the site boundary, under normal and

accident conditions, and that dose rates in general are kept as low as

possible. Every applicant must provide a radiation shielding analysis as

part of the application for a new storage system, or an amendment to an

existing system. This analysis uses a computer model to simulate

radiation penetration through the fuel and thick shielding materials

under normal operating and accident conditions.

The

NRC reviews spent fuel dry cask storage designs to ensure they meet

our limits on radiation doses beyond the site boundary, under normal and

accident conditions, and that dose rates in general are kept as low as

possible. Every applicant must provide a radiation shielding analysis as

part of the application for a new storage system, or an amendment to an

existing system. This analysis uses a computer model to simulate

radiation penetration through the fuel and thick shielding materials

under normal operating and accident conditions.

We review the applicant’s analysis to ensure it has identified all the important radiation-shielding parameters. We make sure they’re modeled conservatively, in a way that maximizes radiation sources and external dose rates. We may create our own computer simulation to confirm the dose rates provided in the application. That helps us to ensure the design meets off-site radiation dose rate requirements under all conditions.

Senior Nuclear Engineer

We’ve

talked before about how the uranium in nuclear fuel undergoes fission

during reactor operations. The fission process turns uranium into a

number of other elements, many of which are radioactive. These elements

continue to produce large amounts of radiation even when the fuel is no

longer supporting a chain reaction in the reactor. So shielding is

necessary to block this radiation, and protect workers and the public.

We’ve

talked before about how the uranium in nuclear fuel undergoes fission

during reactor operations. The fission process turns uranium into a

number of other elements, many of which are radioactive. These elements

continue to produce large amounts of radiation even when the fuel is no

longer supporting a chain reaction in the reactor. So shielding is

necessary to block this radiation, and protect workers and the public.As we discussed in an earlier blog post, the four major types of radiation differ in mass, energy, and how deeply they penetrate people and objects. Alpha radiation—particles consisting of two protons and two neutrons—are the heaviest type. Beta particles—free electrons—have a small mass and a negative charge. Neither alpha nor beta particles will move outside the fuel itself.

But

spent fuel also emits neutron radiation (particles from the nucleus

that have no charge) and gamma radiation (a type of electromagnetic ray

that carries a lot of energy). Both neutron and gamma radiation are

highly penetrating and require shielding.

But

spent fuel also emits neutron radiation (particles from the nucleus

that have no charge) and gamma radiation (a type of electromagnetic ray

that carries a lot of energy). Both neutron and gamma radiation are

highly penetrating and require shielding.Shielding is a key function that dry storage casks perform, but the two main types of dry storage casks are configured in slightly different ways.

For welded, canister-based systems, shielding is provided by a thick (three feet or more) steel-reinforced concrete vault that surrounds an inner steel canister. The thick concrete shields both neutron and gamma radiation, and may be oriented either as an upright cylinder or a horizontal building.

In bolted cask systems, there is no inner canister. Bolted casks have thick steel shells, sometimes with several inches of lead gamma shielding inside. They have a neutron shield on the outside consisting of low-density plastic material, typically mixed with boron to absorb neutrons.

The

NRC reviews spent fuel dry cask storage designs to ensure they meet

our limits on radiation doses beyond the site boundary, under normal and

accident conditions, and that dose rates in general are kept as low as

possible. Every applicant must provide a radiation shielding analysis as

part of the application for a new storage system, or an amendment to an

existing system. This analysis uses a computer model to simulate

radiation penetration through the fuel and thick shielding materials

under normal operating and accident conditions.

The

NRC reviews spent fuel dry cask storage designs to ensure they meet

our limits on radiation doses beyond the site boundary, under normal and

accident conditions, and that dose rates in general are kept as low as

possible. Every applicant must provide a radiation shielding analysis as

part of the application for a new storage system, or an amendment to an

existing system. This analysis uses a computer model to simulate

radiation penetration through the fuel and thick shielding materials

under normal operating and accident conditions.We review the applicant’s analysis to ensure it has identified all the important radiation-shielding parameters. We make sure they’re modeled conservatively, in a way that maximizes radiation sources and external dose rates. We may create our own computer simulation to confirm the dose rates provided in the application. That helps us to ensure the design meets off-site radiation dose rate requirements under all conditions.

No comments:

Post a Comment