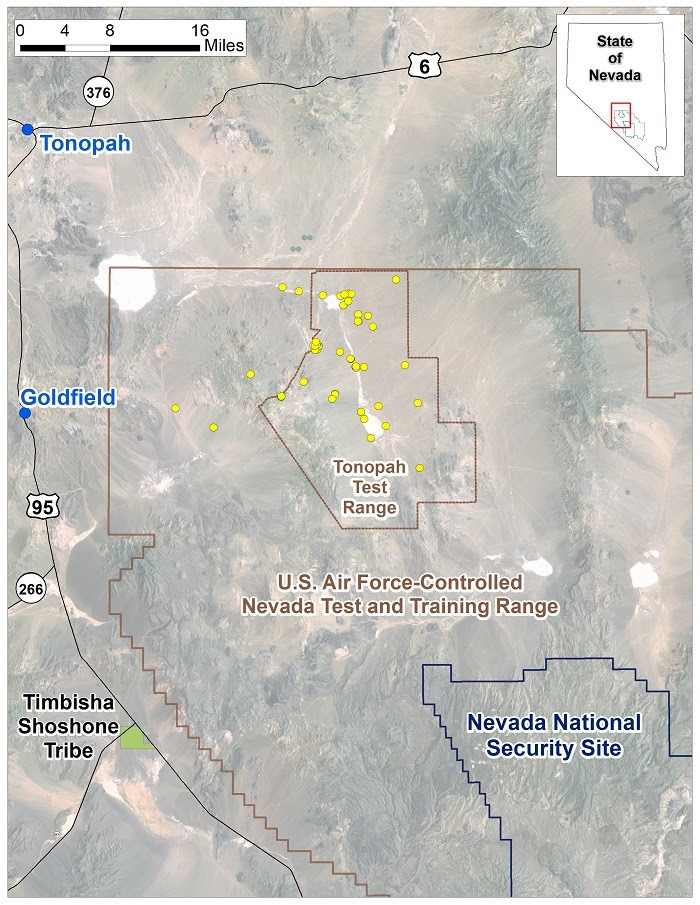

The

DOE Office of Legacy Management is set to assume long-term stewardship

responsibility for 70 sites — represented by the yellow dots in this map

— on the Nevada Test and Training Range where the EM Nevada Program

completed environmental corrective actions in accordance with the

Federal Facility Agreement and Consent Order.

LAS VEGAS – The EM Nevada Program and DOE Office of Legacy Management

(LM) are nearing completion of a transfer of long-term stewardship

responsibilities for 70 sites on the Nevada Test and Training Range

(NTTR), including the Tonopah Test Range (TTR).

The transfer from EM to LM — among EM's ambitious priorities for 2020 — is expected to occur by Sept. 30.

"In

partnership with the Office of Legacy Management and our lead

environmental program services contractor, Navarro Research and

Engineering, the EM Nevada Program is proud to be advancing the transfer

of these sites,” EM Nevada Program Manager Rob Boehlecke said. “We

fully expect to complete the transfer on time and on budget. This

progress supports our federal cleanup mission and shows firsthand what

can be accomplished when a dedicated team works together to accomplish a

goal.”

The transfer process also involves the review and transmission of more than 7,200 documents and records

from the EM Nevada Program to LM. Once the transfer is complete, LM

will assume responsibility for long-term surveillance and maintenance of

the sites in perpetuity.

In accordance with the Federal Facility Agreement and Consent Order (FFACO),

the EM Nevada Program recently completed cleanup at sites on NTTR where

contaminated soil and debris resulted from historic nuclear weapons

testing and support activities. FFACO is a legally-binding agreement

signed in 1996 that outlines a schedule of cleanup and monitoring

commitments.

In

the 1960s, sites at the NTTR were used to test nuclear weapons to

determine if they could be accidentally set off and produce a nuclear

yield. These experiments resulted in the contamination of soil and

debris. During recently completed cleanup of these sites, contaminated soil and debris were transported to the Nevada National Security Site for permanent disposal.

For more information on the EM Nevada Program’s environmental restoration activities, click here.

-Contributor: Michelle French

Oak Ridge Marks Another Teardown on Path to Vision 2020

Demolition

begins on Building K-2500-H. The facility was located near the massive

K-25 gaseous diffusion building and supported demolition efforts for

that project.

OAK RIDGE, Tenn. – The Oak Ridge Office of Environmental Management (OREM) has conducted large-scale demolition at the East Tennessee Technology Park (ETTP) for nearly 15 years.

OREM

and its contractor UCOR are nearing completion of teardowns there, and

one facility they recently demolished had supported demolition work over

the years.

Crews

took down K-2500-H, also known as the Segmentation Shop. Contaminated

equipment, piping, and other items generated by demolition projects were

sent to the facility to be prepared for shipment for disposal.

Constructed in 2007 near the massive K-25 gaseous diffusion building,

the Segmentation Shop was used to process items from K-25, the K-27

gaseous diffusion building, and other facilities that once supported the

site’s uranium enrichment operations.

“The

Segmentation Shop served a crucial purpose, allowing for efficient

disposal of a variety of components pulled from various buildings,” said

James Daffron, acting ETTP portfolio federal project director. “The

fact that it is no longer needed highlights how close we are to

completing site cleanup.”

A

view of the remains from the demolition of the Segmentation Shop as Oak

Ridge crews come closer to achieving Vision 2020. Cleanup efforts at

the East Tennessee Technology Park will remove more than 13 million

square feet of facilities.

While

crews have completed demolition of all facilities that previously

supported uranium enrichment operations, the Segmentation Shop became

the latest in a long list of unneeded buildings that crews have removed

at ETTP.

Only

a handful of unneeded structures remain at the site. Demolition and

major cleanup activities are expected to be completed at ETTP this year —

a goal known as Vision 2020.

It will account for the elimination of more than 13 million square

feet, marking the first time in the world an entire uranium enrichment

complex is removed. More than 12 million square feet of the complex has

been removed already.

OREM

and UCOR are working together to transform ETTP into a multi-use

industrial park, national park, and conservation area for the community.

That vision has already started to become a reality. OREM has

transferred almost 1,300 acres at ETTP for economic development, with

another 600 acres slated for transfer in the years ahead. OREM has also

set aside more than 100 acres for historic preservation and placed more

than 3,000 acres in conservation for community recreational use.

-Contributor: Wayne McKinney

EM Names New WIPP, Los Alamos Managers, Deputy Assistant Secretary for Safety, Security

EM has named new managers for the Carlsbad and Los Alamos

field offices, and a new Deputy Assistant Secretary for Safety,

Security, and Quality Assurance, among leadership updates at its sites

and at headquarters.

Reinhard

Knerr has been selected as manager of the Carlsbad Field Office (CBFO),

where he will oversee operations at the Waste Isolation Pilot Plant

(WIPP). He will transition from his current role as DUF6 Federal Project

Director at the Portsmouth/Paducah Project Office where he supervises the depleted uranium hexafluoride (DUF6) conversion facilities at the Portsmouth, Ohio and Paducah, Kentucky sites.

Knerr

has held leadership and strategic planning roles at the Paducah site

since 2004, including managing environmental remediation work,

transitioning the site’s gaseous diffusion plant from the United States

Enrichment Corporation back to the Department of Energy, and initiating

utility and infrastructure optimization projects. He also has served as

the transuranic waste certification team leader at WIPP, and has over

nine years of experience as a nuclear criticality safety engineer

supporting contractor operations at the National Nuclear Security Administration’s Pantex Plant. Knerr holds a Bachelor of Science in nuclear engineering from the Pennsylvania State University.

At

Carlsbad, Knerr will replace Greg Sosson, who has served as acting

manager since December 2019. Sosson will return to EM headquarters to

serve as Deputy Assistant Secretary for Safety, Security, and Quality

Assurance. That position holds broad responsibility for overseeing the

development of strategies, policy, and guidance for safety, security,

and emergency preparedness to support the EM mission.

Sosson

previously held the position of Associate Deputy Assistant Secretary

for Field Operations Oversight at EM headquarters. Prior to joining DOE,

Sosson was in the commercial nuclear industry for 28 years in senior

operations and engineering positions with a focus on safe and efficient

mission accomplishment, including 10 years as a senior reactor operator.

He also spent 10 years as a light and mechanized infantry officer in

the Army Reserve and National Guard. Sosson holds a Bachelor of Science

in mechanical engineering from the Pennsylvania State University and a

Master of Business Administration from Saint Joseph’s University. He is a

licensed professional engineer.

Mike

Mikolanis, who has been serving as Acting Deputy Assistant Secretary

for Safety, Security, and Quality Assurance, will return to his role as

assistant manager for nuclear material stabilization at the DOE-Savannah River Operations Office (DOE-SR).

Kirk

Lachman has been selected as manager of the EM-Los Alamos Field Office,

following a tenure as deputy manager and acting manager of CBFO. Before

joining CBFO, Lachman was the Deputy Chief for Field Operations at EM

headquarters. He has served in a variety of line management and safety

oversight positions from 2010-2017 at the Nevada Field Office. He served

from 2005 until 2010 as the engineering design group supervisor for the

Office of Civilian Radioactive Waste Management in Las Vegas.

Lachman

graduated from the DOE Senior Executive Service Candidate Development

Program as well as the Harvard Senior Executive Fellows Program. He has a

Bachelor of Science in chemical engineering from the University of

Nebraska and a Master of Science in mechanical engineering from Colorado

State University.

Lachman

will replace Thomas Johnson, who has served as acting manager of EM-Los

Alamos since March. Johnson will return to the Savannah River Site,

where he serves as deputy manager of DOE-SR. In that role, Johnson has

broad leadership responsibility for approximately $1 billion in annual

operating and construction activities at SRS in the areas of

environmental stewardship, and nuclear materials processing and

disposition.

Hanford Marks 25 Years of Successfully Treating Wastewater

A

view of the Effluent Treatment Facility’s process floor. Since 1995,

the facility has processed more than 330 million gallons of contaminated

wastewater to remove radioactive and chemical waste.

RICHLAND, Wash. – A significant component of EM’s complex chain of Hanford Site

waste treatment facilities is marking a quarter century of safely

treating contaminated wastewater while stretching the storage capacity

of underground double-shell tanks.

The “Liquid Waste Processing Facilities”

is a term used to collectively describe four primary facilities that

work together to store, treat, and dispose of large volumes of liquid

waste from around the site. The four facilities are the Liquid Effluent

Retention Facility, Effluent Treatment Facility (ETF), Treated Effluent Disposal Facility, and the State-Approved Land Disposal Site.

Since

1995, the four facilities have processed more than 330 million gallons

of contaminated wastewater to remove radioactive and chemical waste,

primarily from the 242-A Evaporator.

That equipment boils liquid tank waste to evaporate water, also called

effluent, to reduce the volume of waste stored in Hanford’s underground

tanks. Waste volume reduction is also critical for single-shell tank

waste retrievals to double-shell tanks.

“Continued

operations and volume management are important to meeting the Hanford

mission need,” said Richard Valle, Tank Farm program manager.

Two

new vessels were installed in the Effluent Treatment Facility in 2019.

The facility is undergoing upgrades as it prepares to support

Direct-Feed Low-Activity Waste operations to begin by the end of 2023.

The

Liquid Effluent Retention Facility is currently designed to store about

23 million gallons of liquid waste until it can be processed at the

ETF. The ETF processes the liquid waste to remove chemical and

radioactive contaminants. Treated hazardous and radioactive effluent

from ETF is then discharged to the State-Approved Land Disposal Site.

The Treated Effluent Disposal Facility collects nonhazardous and

nonradioactive treated wastewaters that are pumped to two infiltration

basins on the site.

“In

2019, the ETF treated 3.4 million gallons of contaminated wastewater,

exceeding its goal for the year by 1.4 million gallons,” said Brandon

McFerran, ETF manager for Washington River Protection Solutions, EM’s

Hanford tank operations contractor.

The

ETF is undergoing upgrades to improve operations and reliability as

crews prepare it to support Direct-Feed Low-Activity Waste operations.

The ETF is part of the planned 24/7 conversion of liquid waste to a safe

solidified glass form in the new Waste Treatment and Immobilization Plant.

-Contributor: Michael Butler

Spent Nuclear Fuel Transfers Support EM’s Commitment to State of Idaho

EM

workers use a crane to lower a canister filled with spent nuclear fuel

into a liner inside the Radioactive Scrap and Waste Facility at the

Idaho National Laboratory Site.

IDAHO FALLS, Idaho – Crews recently completed the first two of nearly 40 shipments of spent nuclear fuel to a temporary storage area at the Idaho National Laboratory (INL) Site

planned for 2020, helping EM move toward meeting its commitment with

the State of Idaho to transfer the material from wet to dry storage by

2023.

Spent

nuclear fuel handlers and other employees with Fluor Idaho, EM’s INL

Site cleanup contractor, retrieved the fuel from an underwater basin at

Chemical Processing Plant (CPP)-666 at the Idaho Nuclear Technology and

Engineering Center (INTEC). They transferred the fuel to a shipping

cask, which was loaded onto a tractor trailer and transported to the

Radioactive Scrap and Waste Facility (RSWF) at the Materials and Fuels

Complex (MFC). The cask was then unloaded from the trailer, placed over

below-ground steel fuel storage liners, and lowered into place.

The

RSWF, measuring almost 450 feet long and 390 feet wide, was originally

built to receive remote-handled transuranic waste. However,

modifications allowed it to serve as a temporary storage area for the

fuel.

“The

first shipments went off perfectly,” said Russ Cottam, Fluor Idaho

spent nuclear fuel manager. “Our crews had practiced the processes using

a mock-up and used a mobile crane and forklift to simulate the

conditions at the RSWF. The placement of fuel at RSWF went according to

plan.”

Equipment operators move a cask filled with spent nuclear fuel to a storage liner at the Radioactive Scrap and Waste Facility.

Workers

are scheduled to make as many as 38 additional shipments of the fuel

from INTEC to RSWF this year, with shipments continuing into 2021.

Beginning

in September last year, equipment operators, engineers, fuel handlers,

fabricators, and others worked as a team to conduct mock-ups of the fuel

transfers at INTEC. Using a cask assembly built by the INTEC

fabrication shop and a cask designed by INTEC engineers, the team

practiced the transfers.

“So

many dedicated people were involved in this effort,” Cottam said.

“Using a mock-up allowed the team to identify challenges, revise

procedures, and perform the steps flawlessly. It was the epitome of a

well thought-out and executed project.”

The

fuel had originated from the Experimental Breeder Reactor-II (EBR-II)

reactor, which operated at the former Argonne National Laboratory-West,

now MFC, from 1964 until 1994. The reactor generated power for the INL

and provided reactor research benefits. Spent nuclear fuel from EBR-II

was transferred to wet storage at CPP-666 from 1986 to 1999.

The

spent nuclear fuel basin at INTEC is now nearly 95 percent empty. Just

two fuel types remain: EBR-II and Advanced Test Reactor (ATR). ATR fuel

continues to be transferred to CPP-603 for dry storage.

-Contributor: Erik Simpson

Shift Technical Engineer Program Growing to Meet SRS Mission Needs

|

EM Update | Vol. 12, Issue 13 | June 16, 2020

|

||

|

|

||

|

||

EM Nevada Transfer of 70 Sites to Legacy Management Nearly Complete | ||

|

Reinhard Knerr has been selected as manager of the Carlsbad Field Office.

|

|

Greg Sosson will serve as Deputy Assistant Secretary for Safety, Security, and Quality Assurance.

|

|

|

|

After

serving as Acting Deputy Assistant Secretary for Safety, Security, and

Quality Assurance, Mike Mikolanis will return to his role as assistant

manager for nuclear material stabilization at the DOE-Savannah River

Operations Office.

|

|

Kirk Lachman has been selected as manager of the EM-Los Alamos Field Office.

|

|

|

| ||

After

serving as acting manager of the EM-Los Alamos Field Office, Thomas

Johnson will return to the Savannah River Site, where he serves as

deputy manager of the DOE-Savannah River Operations Office.

|

||

John

Mills conducts plant gauge checks at the Defense Waste Processing

Facility as part of his job as a shift technical engineer for Savannah

River Remediation at the Savannah River Site.

AIKEN, S.C. – A team of technical engineers is among the many groups growing to support the increased pace of liquid waste operations at EM’s Savannah River Site (SRS).

These

engineers with SRS liquid waste contractor Savannah River Remediation

(SRR) play a key role in daily operations at liquid waste facilities. As

the engineering point of contact on each shift, they work at the Defense Waste Processing Facility

(DWPF) and Tank Farm facilities, home to the underground waste tanks,

helping ensure safe operations, making critical decisions in the field,

and resolving emergent plant issues.

There

are currently two shift technical engineers per shift covering the Tank

Farm facilities and DWPF, and SRR plans to increase it to three per

shift to provide staffing for the ramped-up waste processing expected to

support the new Salt Waste Processing Facility (SWPF). SWPF is the EM

facility that will process the remaining salt waste at SRS, which makes

up about 90 percent of the remaining radioactive waste stored in

underground tanks.

“With

SWPF coming online, there will be more waste transfers, procedure

changes, and emergent issues, and so there is a need to evaluate current

shift technical engineer staffing,” SRR President and Project Manager

Phil Breidenbach said. “The additional technical engineers will provide

increased capability for solving emergent issues on shift without

detracting from their primary role, which is to ensure compliance with

the safety basis.”

More

than 14 engineers have been promoted to shift technical engineer roles

over the last four years, and there are currently 25 in the program —

nine of which are training. Because of the high level of facility

knowledge required, the training and qualification process to become a

shift technical engineer is rigorous. It’s a four-part process:

prerequisites, additional classroom training, on-the-job training, and a

demanding oral examination. It usually takes about a year to become

qualified.

“It

is important to the overall liquid waste mission and day-to-day

operations to identify key people who will perform well as a shift

technical engineer and train them early and thoroughly to take on this

vital role,” Breidenbach said.

For SRR shift technical engineer Annah Garrison, the best part of the job is the people.

“Working

on shift you get to know the people well, and it feels like family,”

said Garrison, who has worked in the position in the tank facilities for

just over two years. “We look out for each other, and we work together

to do the right thing. My shift always challenges me and motivates me to

improve. It feels good to work as a team to accomplish something

together.”

-Contributor: Colleen Hart

|

||

Like EM on Facebook at: https://www.facebook.com/

|

No comments:

Post a Comment