The Case for Near-term Commercial Demonstration of the Integral Fast Reactor

I’m currently in Dubai at the 2012 World Energy Forum, as part of a delegation from the Science Council for Global Initiatives.

Tomorrow (24 Oct) we will run symposium on “New Nuclear”, which will be

chaired by Tom Blees and feature talks from Dr Eric Loewen (GE), Dr

Alexander Bychkov (IAEA), Dr Evgeny Velikhov (Kurchatov Institute) and

me (Dr Barry Brook, University of Adelaide). I will also chair a session

later in the afternoon on “Vision for a Sustainable Future”, just

before the closing address. More at http://bravenewclimate.com/2012/10/23/the-case-for-near-term-commercial-demonstration-of-the-integral-fast-reactor/

I’m currently in Dubai at the 2012 World Energy Forum, as part of a delegation from the Science Council for Global Initiatives.

Tomorrow (24 Oct) we will run symposium on “New Nuclear”, which will be

chaired by Tom Blees and feature talks from Dr Eric Loewen (GE), Dr

Alexander Bychkov (IAEA), Dr Evgeny Velikhov (Kurchatov Institute) and

me (Dr Barry Brook, University of Adelaide). I will also chair a session

later in the afternoon on “Vision for a Sustainable Future”, just

before the closing address. More at http://bravenewclimate.com/2012/10/23/the-case-for-near-term-commercial-demonstration-of-the-integral-fast-reactor/The white paper is given below.

——————–

The Case for Near-term Commercial Demonstration of the Integral Fast Reactor

Demonstrating a credible and acceptable way to safely recycle

used nuclear fuel will clear a socially acceptable pathway for nuclear

fission to be a major low-carbon energy source for this century. We

advocate a hastened timetable for commercial demonstration of Generation

IV nuclear technology, via construction of a prototype reactor (the

PRISM design, based on the Integral Fast Reactor project) and a

100t/year pyroprocessing facility to convert and recycle fuel.1. Synopsis

We propose an accelerated timeframe for realizing the sustainable nuclear energy goals of the Generation IV reactor systems. A whole–system evaluation by an international group of nuclear and energy experts, assembled by The Science Council for Global Initiatives, reached a consensus on the synergistic design choices: (a) a well-proven pool-type sodium-cooled fast reactor; (b) metal fuel, and (c) recycling using pyroprocessing, enabling the transmutation of actinides. Alternative technology options for the coolant, fuel type and recycling system, while sometimes possessing individually attractive features, are hard-pressed to be combined into a sufficiently competitive overall system. A reactor design that embodies these key features, the General Electric-Hitachi 311 MWe PRISM[1] (based on the Integral Fast Reactor [IFR] concept developed by Argonne National Laboratory[2]), is ready for a commercial-prototype demonstration. We advocate a two-pronged approach for completion by 2020 or earlier: (i) a detailed design and demonstration of a 100 t/year pyroprocessing facility for conversion of spent oxide fuel from light-water reactors[3] into metal fuel for fast reactors; and (ii) construction of a PRISM fast reactor as a commercial-scale demonstration plant. Ideally, this could be achieved via an international collaboration. Once demonstrated, this prototype would provide an international test facility for any concept improvements. It is expected to achieve significant advances in reactor safety, reliability, fuel resource sustainability, management of long-term waste, improved proliferation resistance, and economics.

2. Context

When contemplating the daunting energy challenges facing humanity in the twenty-first century in a world beyond fossil fuels, there are generally two schools of thought[4].

One is to take a scattergun approach, which emphasizes energy efficiency, a gamut of actual and potential clean, low-carbon energy systems, and a hope of future technological advances to solve currently intractable problems like large-scale energy storage. Those who espouse such a view sometimes grudgingly admit that a large component of natural gas will be needed to ‘fill the gaps’ and often support the view that the majority of humanity will have to learn to be content with consuming much less energy than the customary level common in developed countries.

The other perspective sees a way out of the climate/energy/population dilemma in the development and deployment of environmentally benign, fit-for-service technologies that can provide the vast amounts of energy that will be (and are being) demanded, over many millennia into the future[5]. This view not only recognizes that people who are accustomed to energy wealth (or aspire to it) will be loath to give it up, but that there will be no reason to do so. In fact, vast amounts of energy will be required in order to rectify the damage already done to the environment, and to avoid further damage and resource depletion in the future.

The latter viewpoint—sometimes derisively referred to by proponents of the former as the ‘techno-fix’ mindset—is the general outlook of an international think tank called The Science Council for Global Initiatives (SCGI). On October 2-3, 2012, SCGI assembled key scientists and policymakers at the University of California Berkeley to discuss the most pivotal technology in the SCGI spectrum: the Integral Fast Reactor (IFR).

Participants at the conference came from nine countries: Australia, Canada, China, Japan, Russia, South Korea, Sweden, United Kingdom and the USA. (Since the UK government is currently weighing an offer from GE-Hitachi regarding a proposal to construct PRISM reactors in Britain, our UK guests participated as observers and are understandably constrained from taking a position on fast reactor deployment.) Most of these had deep knowledge of fast nuclear reactor systems and global energy policy. Several of the countries represented have fast reactor research projects ongoing, have had them in the past, or are considering them for the future. The goal of this conference was to share the current state of fast reactor development in each country, reach a consensus on design attributes of a system that could be feasibly deployed within this decade, and explore ways in which international cooperation can be mustered to move as quickly as possible from the experimental to the commercial phase.

The

Emiratis are serious about nuclear for low-carbon energy, as attested

to by these banners in their main convention centre a the World Energy

Forum in Dubai.

The

Emiratis are serious about nuclear for low-carbon energy, as attested

to by these banners in their main convention centre a the World Energy

Forum in Dubai.At the turn of the twenty-first century a group of nine nations agreed to collaborate in the development of advanced nuclear power systems capable of meeting the energy needs and aspirations of the new millennium. These nine nations were soon joined by several other countries to form the Generation IV International Forum, GIF[6]. (Generation IV refers to the next-generation nuclear power systems in the incremental technical evolution—Generation I through III—since the dawn of the nuclear age.[7])

The goals of GIF involve four categories: sustainability, economics, safety and reliability, and proliferation resistance and physical protection. Six promising nuclear technology concepts were selected after an initial evaluation of a wide variety of systems, with an aspiration for ongoing development to 2030 and beyond. (In an evaluation of 19 reactor systems by the Gen IV Roadmap Integration Team in 2002, the IFR ranked number one overall.[8]) The purpose of the Berkeley SCGI conference was to promote international cooperation in hastening the move from R&D to a near-term demonstration of a commercial-scale Gen IV system. The pressing nature of climate change, burgeoning population growth, and the socio-political imperative to demonstrate solutions to the perceived problems of current-generation nuclear energy systems, demand an end to interminable delays.

Until very recently, deployment of fast reactor systems was characterised as plausible only decades into the future. Then late last year, in November of 2011, GE-Hitachi Nuclear made a paradigm-shifting offer to the United Kingdom, which was seeking a solution to disposition of that nation’s plutonium inventory[9] (at 112 tons, the largest such stockpile in the world). GEH submitted an offer to build a pair of PRISM reactors in the UK to solve their plutonium quandary in about five years, with the recouping of costs coming via a set fee for each kilo of plutonium that was successfully processed by the PRISMs[10] and from the electric power generated in the process.

4. The Integral Fast Reactor System Design

The Integral Fast Reactor (IFR) is a Gen IV system that meets the goals of GIF, backed by decades of engineering-scale R&D at Argonne National Laboratory and elsewhere. The IFR is ready for commercial demonstration. It has the following essential features: (i) liquid sodium coolant, (ii) pool configuration, (iii) metallic fuel, and (iv) fuel recycling using pyroprocessing[11].

Liquid sodium coolant has by far the most operational experience in experimental fast reactors, and offers a number of advantages: it transfers heat from the fuel efficiently; it can absorb significant heat without excessive temperature rise; its boiling point is far above operating temperatures, yet it melts at a fairly low temperature; it does not react chemically with either the reactor structural materials or the metallic fuel; it is stable both chemically and under irradiation; its activation products are short-lived; and finally, it is cheap and commonly available. These attributes allow operation of the fast neutron reactor at atmospheric pressure, a characteristic that has many obvious safety and structural advantages. The main disadvantages of sodium are its opacity and its high chemical reactivity with oxygen in water or air. These disadvantages are overcome by design.

The reactor pool has both primary and secondary guard vessels with no penetrations below the sodium surface level, to minimize the possibility of leakage, and is surrounded by inert argon gas. This configuration makes it simple to isolate the radioactive primary coolant from the steam generator. A non-radioactive secondary sodium circuit gives up its heat to the steam generators in a separate structure away from the reactor core, and if leakage does occur, it is blanketed by an inert argon atmosphere and would leak slowly out of any pipe break because the circuit is not pressurized. The reactor pool contains enough sodium to absorb the transient heat under accident conditions, to allow safe reactor regulation, and to permit passive circulation and heat removal.

The metal fuel, a ternary alloy of U-Pu-Zr, is a crucial choice for the IFR. The long-standing problem of fuel swelling that plagued early use of metal fuel and severely limited fuel burnup was solved by allowing the fuel slugs to fit loosely within the stainless steel cladding, with the necessary thermal bond provided by a sodium layer between fuel and cladding. Fission product gases are collected in a plenum above the fuel. This simple innovation allows for long irradiation times and high burnup (once fuel swells to the cladding’s inner surface, fission-gas pores interconnect and the gas is released to the plenum without further swelling). The metal fuel not only allows for high breeding ratios and a simple yet proliferation-resistant method of recycling and recasting (see below); it also confers significant safety features. Little heat energy is stored in the fuel and is rapidly transferred to the sodium coolant; furthermore, negative reactivity feedbacks occur as core temperature rises, quickly reducing reactivity due to increased neutron leakage.

The pyroprocess for fuel recycling uses an electrochemical system to separate actinides from the fission product waste within a hot molten-salt bath, yet it cannot yield a purified plutonium stream (the pyroprocessing heavy-metal product is inevitably mixed with minor actinides and highly radioactive trace lanthanides, providing substantial proliferation resistance). The fission products and cladding hulls are immobilized in zeolite and vitrified, whilst the actinides can be readily re-formed into metal fuel pins using a simple injection-casting method that can be done remotely. The pyroprocess lends itself to a compact plant design without aqueous byproducts, thereby offering significant potential cost savings and environmental benefits.

The reason for recommending these design choices in preference to potential fast reactor alternatives (e.g., oxide fuel, lead coolant or loop configuration), are detailed in the 2011 book by Till & Chang, Plentiful Energy[12].

In summary, the key design elements of the IFR – metallic fuel, sodium coolant and pool vessel configuration, work together as a complementary system to bring out the best in the fast reactor and yield many desirable, synergistic characteristics. These component choices, along with the associated proliferation-resistant and relatively inexpensive process for recycling the used fuel and the technology for disposal of the residual waste, define an advanced nuclear system that can truly be called revolutionary in its possibilities. In the words of the Nobel laureate physicist Hans Bethe, “All the pieces fit together.”

Next-generation nuclear energy, as exemplified by the IFR design, offers a means to produce vast quantities of zero-carbon and reliable electricity and process heat. By taking advantage of the superior physical properties of plutonium in a fast neutron spectrum for converting essentially all of the mined uranium into useful fissile material, the IFR can change in a fundamental way the outlook for global energy on the necessary massive scale[13]. These resource extension properties multiply the amount of usable fuel by a factor of over a hundred, allowing demand to be met for many centuries with fuel already at hand, by a technology that is known today, and whose properties are largely established. All that is required now is to complete the final steps in a prototype demonstration to give confidence for a large-scale deployment.

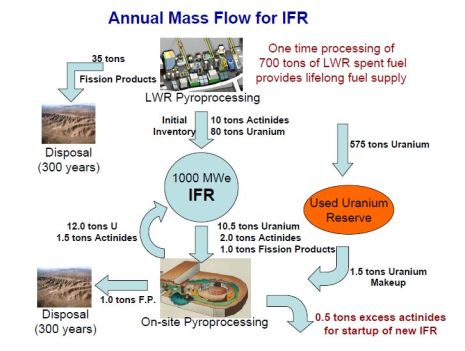

Below: Mass flow diagram for off-line stand-alone pyroprocessing facility using light-water reactor (LWR) waste to provide fuel for a gigawatt-sized integral fast reactor (IFR) plant operating in closed-cycle mode.

5. Alternative Technology Choices and Implications

The GIF selected six promising next-generation nuclear technologies on which to focus for research, development and deployment. Some of them have the benefit of actual experimental experience, while others are as yet theoretical. The Berkeley conferees discussed a variety of reactor types and components, albeit not an exhaustive list since exploring all those options would require a discussion of a complexity and depth beyond the scope of a two-day conference. Our intention was rather to explore technologies that readily meet the overall goals and can be demonstrated at a commercial scale now, since climate change, population growth and other critical issues for 21st century sustainability will not wait for long-term research and development. Replacement of fossil fuels is urgently needed to sustain our world’s well-being.

It should be noted here that virtually all of the conference participants were in agreement that construction of advanced water reactor designs is imperative to meet the near-term electricity demand growth. Light-water reactors (LWR) of any stripe, however, produce only a tiny fraction of the potential energy in uranium, less than 1%. Fast reactors, in contrast, unlock nearly all of it. The IFR, with its metal-fuel system and pyroprocessing, is able to utilize the actinides to such an extent as to essentially solve the waste problem by reducing the radiological toxicity of the waste products from hundreds of thousands of years to a mere few hundred years. Even if the “million-year problem” of LWR spent fuel is more a political than a technical challenge (given the small volume of the waste stream), nevertheless the issue of public perception of that issue is the one that guides nuclear policy in many countries[14]. As such, the transition to fast reactors and a closed nuclear fuel cycle is both a technical advancement and a political enabler for nuclear power of all kinds.

The Berkeley group looked at other fast reactor systems besides the IFR/PRISM that are in the R&D phase in various countries today, in order to weigh the pros and cons vis-à-vis IFRs. This included discussion of alternative coolants, such as lead, and fuel forms such as uranium nitride or oxide. On balance the arguments presented by the conferees favored the use of sodium coolant and metal fuel, within an IFR-like system. It was suggested that perhaps the oxide-fueled Monju experimental fast reactor in Japan might get a new lease on life if it could be converted to metal fuel. Given the politically sensitive situation of nuclear power in Japan after Fukushima that makes the development of super-safe nuclear design more urgent than ever, the controversial Monju could well become a model of future nuclear power in Japan.

One of the issues most often mentioned when discussing sodium-cooled fast reactors—by far the type with the most reactor-years of experience worldwide—is the chemical reactivity of sodium, which burns upon contact with air (though with a very cool flame) and reacts quite dramatically upon contact with water. Yet sodium has several compelling advantages in fast-reactor operation: superior heat-exchange properties, virtually no corrosive effect on reactor components even after decades of operation, short half-life of sodium isotopes that form in the reactor vessel, etc. (see previous section). Some advocates of other systems characterize sodium’s volatility as a deal-breaker. But the intermediate loop that transfers heat from the reactor vessel to the steam generator contains only non-radioactive sodium, with the steam generator isolated in a separate structure, assuring that in the highly unlikely event of a sodium-water reaction there will be no danger to the primary system and no chance of radioactive material being involved. This design means that the unfairly characterized sodium problem is nothing more than an engineering design issue, involving a common element that has been used in industrial processes for well over a century. With over 300 reactor-years of experience with sodium-cooled fast reactors around the world, not a single instance of sodium-water interaction resulting in radioactive release has been recorded[15].

The conferees also touched on other fast reactor and thermal reactor systems being considered today, in varying degrees of development: molten fluoride salt thorium reactors (LFTRs), liquid-salt-cooled pebble fuel systems, etc.[16] While some of these hold promise, none are near the level of readiness for near-term commercial-prototype deployment as the PRISM reactor and its metal-fuel technology. In addition, none of the immediate prospects can match the IFR concept in meeting all the goals of the Gen IV initiative.

6. The Way Forward

There is a pressing need to: (a) displace our heavy dependence on fossil fuels with sustainable, low-carbon alternative energy sources over the coming decades to mitigate the environmental damage of energy production and underpin global energy security[17], and (b) demonstrate a credible and acceptable way to safely deal with used nuclear fuel in order to clear a socially acceptable pathway for nuclear fission to be a major low-carbon energy source for this century. Given the enormous technical, logistical and economic challenges of adding carbon capture and storage to coal and gas power plants, we are faced with the necessity of a nearly complete transformation of the world’s energy systems. Objective analyses of the inherent constraints on wind, solar, and other less-mature renewable energy technologies inevitably show that they will fall short of meeting future low-emissions demands. A ‘go slow, do little’ approach to energy policy is not defensible given the urgency of the problems society must address, and the time required for an orderly transition of energy systems at a global scale. As such, SCGI advocates a near-term deployment of the Integral Fast Reactor.

What is needed now is a two-pronged approach, for completion by 2020 or earlier, that involves: (i) demonstration of the pyroprocessing of LWR spent oxide fuel, and (ii) construction of a PRISM fast reactor as a prototype demonstration plant, to establish the basis for licensing and the cost and schedule for subsequent fully commercial IFR plants. Once demonstrated, this commercial IFR will be expected to show very significant advances in nuclear safety, reliability, nuclear fuel sustainability, management of long-term waste, proliferation resistance, and economics. The time has come to capitalize on this exceptional energy technology, with the benefits of this development extending throughout the global energy economy in the 21st century.

7. Follow Up

For further information on the IFR and related technology options, visit The Science Council for Global Initiatives website: http://thesciencecouncil.com (This resource includes a list of members from science, engineering and policy backgrounds, contact details, and various technical publications and popular articles).

SCGI is an international nonprofit organization dedicated to informing the public and policymakers about technologies and strategies that can lead to an energy-rich world. SCGI provides a forum for many of the world’s prominent scientists, authors and activists to collaborate and share their knowledge regarding solutions to the world’s energy, resource and environmental problems.

SCGI’s ambitious aims are to advocate near-term deployment of cutting-edge technologies, such as integral fast reactors, zero-emission vehicles and plasma recyclers. Such technologies can realistically eliminate most air pollution, recycle spent nuclear fuel, bring the fossil fuel era to an end, prevent resource wars (including potential water wars), effortlessly recycle virtually all of our waste products, power our vehicles with zero-emission energy systems, provide abundant energy and fresh water to every nation, reduce human-caused greenhouse gas emissions to a trickle, diminish the world’s nuclear arsenals, turn old nuclear weapons into energy, and promote other technologies that, once commercialized and deployed on a large scale, can lead us to a sustainable post-scarcity era.

[17] http://www.sciencedirect.com/science/article/pii/S0301421511009189

———–

No comments:

Post a Comment