An Outage Twist: Degraded bolts at New York Nuclear Plant Warrant Attention

Posted by on April 27, 2016

Public Affairs Officer

Region I

When the Indian Point Unit 2 nuclear power plant entered a refueling and maintenance outage in early March, the to-do list included a task born of industry operating experience, both in the United States and overseas.

Specialists

were geared up to check on the condition of bolts employed in the

reactor vessel at the Buchanan, N.Y., facility. These are the kind of

bolts you likely wouldn’t find at your local hardware store. Rather,

they are made of a stainless-steel alloy capable of withstanding

decades’ worth of neutron bombardment, as well as extraordinarily high

temperatures and pressure.

Specialists

were geared up to check on the condition of bolts employed in the

reactor vessel at the Buchanan, N.Y., facility. These are the kind of

bolts you likely wouldn’t find at your local hardware store. Rather,

they are made of a stainless-steel alloy capable of withstanding

decades’ worth of neutron bombardment, as well as extraordinarily high

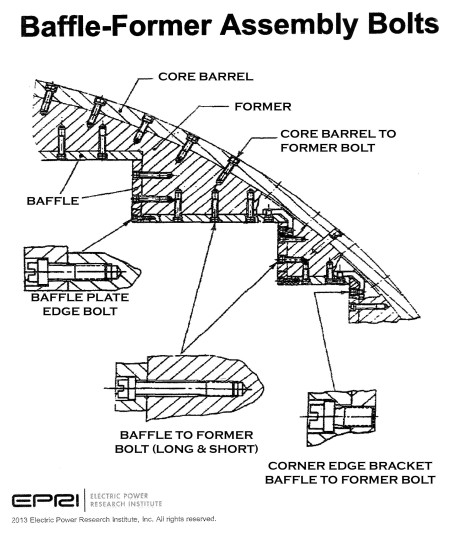

temperatures and pressure.Measuring about 2 inches in length and 5/8ths of an inch in diameter, the bolts hold in place a series of vertical metal plates. Known as baffle plates, they help direct water up through the nuclear fuel assemblies, where it is heated and subsequently used for power production.

The baffle plates are attached to eight levels of horizontal plates called baffle-former plates, which are in turn connected to the reactor core barrel.

As far back as the late 1980s, cracking was identified in baffle-former bolts – the bolts securing the baffle plates to the baffle-former plates — in pressurized-water reactors (PWRs) in France. (Both Indian Point Units 2 and 3 are PWRs.) The degradation is caused by what is known as irradiation-assisted stress corrosion cracking.

In response, the U.S nuclear industry began checking on these bolts in a small number of domestic PWRs on a sample basis.

The NRC staff also made use of a communications tool called an Information Notice to advise U.S. plant owners of what had been observed in Europe. A March 1998 notice let U.S. plant owners know that the baffle-former bolt cracking reported in foreign PWRs had occurred at the juncture of the bolt head and the shank, a location not accessible for visual examination.

Several U.S. plants subsequently evaluated their baffle-former bolts and in some cases replaced a sizable number.

Jumping ahead, the Electric Power Research Institute developed a standard industry program for the aging management of PWR reactor vessel internals and submitted it to the NRC in January 2009. The NRC staff approved the approach in an agency safety evaluation issued in December 2011 and then published in January 2012 as MRP-227-A. (MRP is short for Materials Reliability Program.)

Under this new standard, U.S. PWRs were to conduct an initial ultrasonic examination of all of their baffle-former bolts when the plant had between 25 and 35 effective full power years of service.

This is exactly what was being done at Indian Point Unit 2 during the current outage. It was adhering to the standards of MRP-227-A. In the course of this review, it was determined that 227 of 832 baffle-former bolts at the plant were degraded, which means any indication of cracking. What’s more, two bolt heads were missing.

The number of degraded baffle-former bolts was the largest seen to date at a U.S. reactor.

Entergy, Indian Point’s owner, is in the process of analyzing the condition and replacing the degraded bolts. It will also assess any implications for Indian Point Unit 3, though that reactor is believed to be less susceptible to the condition for several reasons, including fewer operational cycles.

As for the NRC, we will independently review the company’s analysis and bolt-replacement plans to ensure safety. The results of those reviews will be documented in an upcoming inspection report for the plant.

We have already had a metallurgical specialist on-site reviewing the company’s evaluations of the bolts and have agency experts reviewing the matter.

More information will be forthcoming on the issue. However, it’s important to note that the NRC staff will ensure the condition is fully understood and addressed prior to the plant returning to service. The NRC staff will also consider all available information in evaluating if changes are needed to the current inspection programs for these bolts across the industry.

No comments:

Post a Comment