RICHLAND, Wash. – EM Senior Advisor William “Ike” White visited the Hanford Site last week to view progress on the environmental cleanup mission.

“Despite unprecedented challenges caused by the ongoing COVID-19 pandemic, the Hanford team has demonstrated an ability to adjust, adapt, and move the cleanup mission forward,” said White. “They are progressing the Direct-Feed Low-Activity Waste (DFLAW) system that puts tank waste treatment on the horizon at Hanford, and addressing risks from the site’s plutonium production legacy.”

White got a firsthand look at advancements on several projects critical to the DFLAW system that will transform the Hanford Site by enabling a shift to tank waste treatment operations. The approach is a system of interdependent projects and infrastructure improvements that will operate together to send pretreated waste from Hanford’s tank farms directly to the Low-Activity Waste Facility at the Waste Treatment and Immobilization Plant (WTP).

White began his visit at the AP Tank Farm, where the recent delivery of a pretreatment system for tank waste marked the last piece of the physical DFLAW system to be put in place at Hanford. At WTP, White saw specially fabricated containers that were delivered to the site in October that will hold vitrified waste after it is treated so that it can be safely disposed.

EM Senior Advisor William “Ike” White, right, stopped by the Waste Treatment and Immobilization Plant during a visit to the Hanford Site last week and saw the first 20 containers that will hold waste simulant and tank waste that is vitrified, or immobilized in glass. Also pictured is Waste Treatment Completion Company Nuclear Facility Manager Mike Huyck.

|

EM Senior Advisor William “Ike” White, right, visited the Waste Treatment and Immobilization Plant’s Analytical Laboratory, the first nuclear facility in the plant to move from startup testing to commissioning following construction. The laboratory will analyze approximately 3,000 samples a year to ensure low-activity tank waste immobilized in glass meets disposal requirements. Also pictured is Waste Treatment Completion Company Chemist Andrew Killgore.

White also visited the plant’s Analytical Laboratory, which recently became the first nuclear facility at the plant to finish startup testing, and he visited the plant’s Effluent Management Facility. White rounded out his first day at Hanford with a look at improvements to the disposal facility where tens of thousands of containers of vitrified low-activity waste will be placed.

In addition to viewing progress on Hanford’s tank waste mission, White visited a number of projects where workers are reducing significant risks and remediating contamination from Hanford’s national security mission.

At the Waste Encapsulation and Storage Facility, White got a look at the latest preparations for transferring capsules of highly radioactive cesium and strontium from underwater storage to dry storage casks.

At a visit to a mock-up used for practice and training, updates were provided on work to excavate highly radioactive soil from below Hanford’s 324 Building.

EM Senior Advisor William “Ike” White, right, ended his visit to the Hanford Site last week with a stop at a mock-up of a former plutonium processing laboratory located near Richland, Washington, and the Columbia River, where workers are preparing to excavate highly radioactive soil from below the 324 Building. Also pictured is Ben Vannah with EM Richland Operations Office.

While at the 200 West Pump and Treat Facility, White congratulated workers on reaching the goal of treating approximately 2 billion gallons of groundwater this year.

White was also briefed on work getting underway to stabilize three aging underground waste disposal structures located in the footprint of the Plutonium Finishing Plant demolition area. See more on this project in this issue of the EM Update.

“With the risk reduction work and the transformative progress on the tank waste mission, 2020 represents an inflection point for Hanford,” said White. “The work being accomplished puts the site on a clear path to tank waste treatment and additional risk reduction in the years ahead.”

Milestone Reached as First Shipment of Uranium Oxide Reaches Final Disposition

Workers at the Paducah Site load depleted uranium oxide cylinders onto a specialized railcar for shipment to the Waste Control Specialists Federal Waste Facility.

ANDREWS, Texas – Marking a milestone for EM’s first-of-a-kind Depleted Uranium Hexafluoride (DUF6) Conversion facilities, the first shipment of depleted uranium oxide (DUO) product recently left the Paducah Site in Kentucky and safely reached its final destination.

“Completing the first shipment of depleted uranium oxide opens an important chapter in the story of the DUF6 Conversion Project,” said Robert Edwards, manager of EM’s Portsmouth/Paducah Project Office. “It is significant because it safely and efficiently addresses one of the Department’s legacy priorities.”

The material arrived in six storage cylinders in a specifically modified 55-foot gondola rail car at the Waste Control Specialists (WCS) Federal Waste Facility in Andrews. A low-level crystalline powder, DUO is one of two end-products of the DUF6 conversion process — the other being hydrogen fluoride that is dispositioned elsewhere.

A Waste Control Specialists Federal Waste Facility crew in Texas offloads one of the first depleted uranium oxide cylinders to reach final disposition.

The Energy Department’s DUF6 inventory resulted from 50 years of uranium enrichment at U.S. gaseous diffusion plants. More than 700,000 metric tons of the material is safely maintained in storage at Paducah and its sister site near Portsmouth, Ohio. Over the next few decades, some of the remaining inventory will be disposed in licensed offsite facilities and some will be reused.

Zack Smith, president and project manager of EM’s DUF6 operations and maintenance contractor, Mid-America Conversion Services, credited his company’s partnership with the United Steelworkers, DOE, and the WCS facility for the milestone. He noted that numerous procedures and plans were developed while adhering to pandemic protocols.

"The inaugural oxide shipment demonstrates the full mission capability for the DUF6 Project, and a job well done by a very capable team," Smith said.

-Contributors: Kearney Ackermann, Brad Mitzelfelt, Tom Simmons, Waste Control Specialists

EM Nevada Reaches 75% Completion of Groundwater Mission

Aerial images of craters in Yucca Flat including Sedan Crater, located at the north end of Yucca Flat.

LAS VEGAS – The EM Nevada Program recently reached the final stage of groundwater activities — regulatory closure — at the third of four underground test area corrective action regions at the Nevada National Security Site (NNSS).

With the closure of the Yucca Flat and Climax Mine groundwater area, EM Nevada’s overall groundwater mission at the NNSS is now 75% complete.

“The successful closure of our second groundwater corrective action area in 2020 alone is a testament to the hard work of dedicated professionals with the EM Nevada Program, as well as our lead contractor, Navarro Research and Engineering, over the course of many years,” EM Nevada Program Manager Rob Boehlecke said. “With this accomplishment, we are now three-quarters of the way toward completing our overall groundwater mission in Nevada, an effort that promises to come in both ahead of schedule and well under budget.”

The Yucca Flat and Climax Mine corrective action region is located in the northeast portion of the NNSS, about 85 miles from Las Vegas, and contains groundwater impacted by historic nuclear weapons and device testing at the site. The area was host to 750 underground nuclear detonations from 1951 to 1992, three of which occurred at Climax Mine, with the remaining 747 occurring at Yucca Flat.

A view from Sedan Crater looking at Flat Top Mountain with Climax Mine visible on the foothill.

A groundwater well at the Yucca Flat and Climax Mine corrective action unit.

The closure of the Yucca Flat and Climax Mine groundwater area represents the second such accomplishment for EM Nevada this year alone. In April, the program earned regulatory approval for closure at the Rainier Mesa and Shoshone Mountain groundwater area, a milestone reached three years ahead of schedule, saving $5 million in federal funding.

Combined, these dual successes cap off more than 35 years of testing, analysis, and modeling work in the Rainier Mesa, Shoshone Mountain, Yucca Flat, and Climax Mine groundwater areas, which has led EM Nevada to an even better understanding of the nature and movement of groundwater under the NNSS. Based on these extensive, expert observations, it is understood that radiologically contaminated groundwater at the NNSS will likely never pose a threat to the public.

To safely and successfully accelerate its groundwater mission, EM Nevada has broadly adopted the use of risk-informed decision-making, which prioritizes the protection of human health and the environment, while considering future land use, in the development of cleanup strategies. As a result of this approach, the accelerated closure of all groundwater areas at the NNSS is anticipated to result in $80 million in savings under initial baseline estimates, with the timeline expedited by two full years.

Click here for more information EM Nevada’s groundwater mission at the NNSS.

-Contributor: Jesse Sleezer

Idaho Site Continues Cleanup Progress Under 25-Year-Old Landmark Agreement

IDAHO FALLS, Idaho – It’s been 25 years since EM, the state of Idaho, and U.S. Navy signed a landmark agreement providing timelines for offsite transuranic waste shipments, the transfer of spent nuclear fuel from wet to dry storage, and the treatment and shipment of high-level radioactive wastes.

In two and a half decades, EM has met more than 90% of milestones outlined in the 1995 Idaho Settlement Agreement on or ahead of schedule. In other instances, EM and the state have renegotiated milestones.

“The Idaho Settlement Agreement has been extremely beneficial to the Department, the state of Idaho, and our stakeholders in that it provided the vision to safely disposition legacy wastes and spent nuclear fuel,” EM Idaho Cleanup Project Manager Connie Flohr said. “We’ve made monumental progress in meeting our commitments, which in turn has paved the way for a long and meaningful nuclear energy mission in Idaho.”

Key to the agreement is the milestone to ship offsite 65,000 cubic meters of transuranic waste that was sent to the site for aboveground storage from the former Rocky Flats Plant and other offsite generators from 1970 until the late 1980s.

EM and cleanup contractor Fluor Idaho retrieved the last of that waste in 2017 and completed the treatment of transuranic waste debris last fall. To date, more than 60,000 cubic meters of transuranic waste has been shipped out of Idaho for permanent disposal. Based on a projected shipping schedule from the Waste Isolation Pilot Plant in New Mexico, the remaining transuranic waste will leave Idaho in the next decade.

In 2008, a record of decision was signed that incorporated two milestones into the agreement focused on exhuming, repackaging, and shipping targeted buried radioactive and hazardous waste sent to Idaho from 1954 to 1970. EM met one of the milestones after exhuming a minimum of 7,485 cubic meters of waste. EM is set to reach the second milestone next year after completing remediation of a combined 5.69 acres of a landfill containing buried waste.

Another critical milestone of the agreement is the transfer of spent nuclear fuel from a water-filled basin to dry storage by 2023. Two types of fuel remain in wet storage, and the basin is now 95% empty. The final disposition path for the remaining spent nuclear fuel is contingent upon the opening of a geologic waste repository or interim storage location.

EM continues progress on the Integrated Waste Treatment Unit, which will convert approximately 900,000 gallons of liquid sodium-bearing waste to a granular solid. The waste was generated during historic spent nuclear fuel reprocessing campaigns that ended in 1992. EM soon is scheduled to launch a final 50-day demonstration at the facility using a simulant. That demonstration will take place after facility modifications are completed this year, as the facility nears startup of operations.

Under the agreement, EM is required to retrieve, treat, repackage, and prepare 4,400 cubic meters of a granulated high-level radioactive waste called calcine to ship for out-of-state disposal by 2035. Crews are testing technologies to enter a bin set to retrieve 220 cubic meters of the waste and transfer it to another bin set. Once emptied, the first bin set would be closed under federal regulations. The bins are a series of long cylinders, and the number of bins in each set varies.

“While there is still much work to do, I’m proud of what’s been accomplished in Idaho over the last 25 years,” said Flohr. “I appreciate the dedication of all employees involved in this effort as well as the support of our stakeholders, the Shoshone-Bannock Tribes, the congressional delegation, and the state of Idaho.”

-Contributor: Erik Simpson

Hanford Begins Stabilizing Aging Underground Disposal Structures

Workers at the Hanford Site made final connections between a pipe sticking up out of one of three aging underground structures being stabilized and a grout delivery system.

RICHLAND, Wash. – EM Richland Operations Office (RL) and contractor CH2M HILL Plateau Remediation Company (CHPRC) have begun filling the first of three aging underground structures on the Hanford Site with engineered grout in accordance with engineering recommendations.

The interim measure will mitigate the risk of collapse and the potential for contamination spread until a remedy to remove, treat, and dispose of the material in the structures is implemented.

The three structures, located near the former Plutonium Finishing Plant on Hanford’s Central Plateau, received liquid waste during Hanford’s plutonium production operations and contain residual radioactive and chemical contamination. Recent evaluations determined the structures are at risk of age-related failure.

“This is a major step forward in reducing risk at the Hanford Site,” said Al Farabee, Hanford’s senior technical advisor for the project. “Filling these structures with engineered grout will further protect workers and the environment, while not precluding future remedial actions or final closure decisions.”

Devan Smith, an engineer for EM Richland Operations Office contractor CH2M HILL Plateau Remediation Company, monitors progress as workers prepare to stabilize three aging underground disposal structures by filling them with engineered grout.

Grout has been used to safely stabilize other structures at Hanford, including the Plutonium Uranium Extraction (PUREX) Plant waste storage tunnel that partially collapsed in 2017 and an adjacent waste storage tunnel in 2019.

This animation shows the grout delivery system being used to stabilize the three structures. The system pumps the engineered grout from trucks through more than 1,500 feet of pipe to the underground structures. The system was successfully tested using a full-scale mock-up last summer.

“I’m proud of the safe and steady progress our team has made on the stabilization project during obviously challenging circumstances last spring and summer,” said Delise Savior, CHPRC project manager. “We look forward to continuing to work collaboratively with the Department of Energy and regulators to safely complete the project as part of ongoing risk-reduction activities on Hanford’s Central Plateau.”

Stabilization of all three structures is expected to be completed by the end of the year.

-Contributor: Joan Lucas

EM Senior Advisor White Discusses Cleanup With Paducah Community Leaders

EM Senior Advisor William “Ike” White told members of the community near EM’s Paducah, Kentucky site recently that the cleanup program remains productive amid the COVID-19 pandemic and continues to maximize telework opportunities for employees.

The virtual meeting with Paducah community leaders and members of the Paducah Area Chamber of Commerce was moderated by chamber president Sandra Wilson and U.S. Rep. James Comer of Kentucky. Portsmouth/Paducah Project Office Manager Robert Edwards also participated in the event.

An expansion of EM’s virtual capabilities may create opportunities to attract the workforce of the future, White said. He talked about EM’s continued focus on attracting talent from colleges and universities in the region surrounding the Paducah Site.

White shared with the group a list of the Paducah Site’s current priorities, which are outlined in EM’s Strategic Vision: The C-400 Complex remediation, C-333 process building deactivation, and infrastructure and utilities improvements.

Meeting participants also discussed the Paducah Area Community Reuse Organization (PACRO). White said he appreciates the organization’s work, which benefits both the community and EM. PACRO has worked on several recycling efforts with the site. White said that communication between EM and the community is essential for discovering new opportunities to work cooperatively.

The virtual meeting was held in lieu of the Paducah chamber’s annual visit to Washington, D.C., which provides chamber members with an opportunity to meet with their congressional delegation, government agencies, and others.

-Contributor: Alyssa Harris

Evaporator Facility Gears Up for Tank Waste Treatment at Hanford

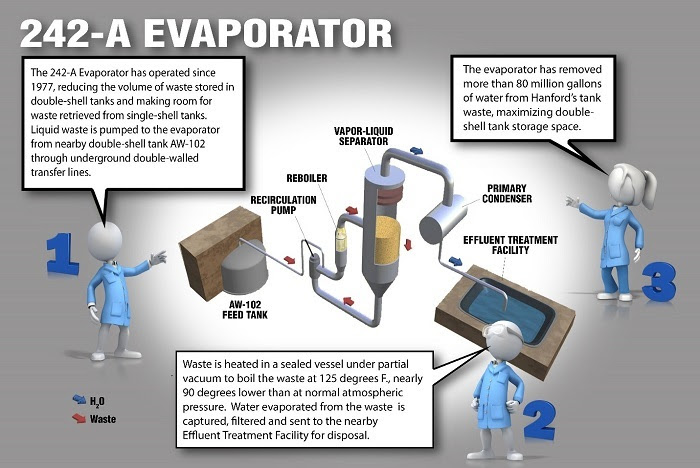

A graphic representation showing how the 242-A Evaporator creates storage space in the double-shell tanks at the Hanford Site.

RICHLAND, Wash. – EM’s Direct-Feed Low-Activity Waste approach will rely on many Hanford Site facilities working together.

The 242-A Evaporator is one of those facilities, which is why ensuring its dependability is a top priority.

The 242-A Evaporator is fundamental to the Hanford Site tank waste mission. EM Office of River Protection (ORP) and contractor Washington River Protection Solutions have completed several major upgrades and repairs at the evaporator, and more are planned.

“These improvements will ensure the evaporator is efficient and dependable for its long-term mission during tank waste treatment operations,” said Paul Hernandez with ORP.

The control room of Hanford’s 242-A Evaporator facility has been upgraded to support the Hanford Site tank waste treatment mission using the Direct-Feed Low-Activity Waste approach. Other upgrades will include adding new waste transfer lines. The evaporator has played a vital role for more than 40 years, creating storage space in Hanford’s double-shell tanks by boiling liquid tank waste to remove water and most volatile organics, reducing the volume by as much as 40%. Vapor from the boiling waste is condensed, filtered, and sent to Hanford’s Effluent Treatment Facility for disposal. The remaining slurry is sent back to a double-shell waste tank. Recent improvements include a new instrument air dryer and a new air receiver tank and piping. The team also upgraded the facility’s monitoring and control system, updating system hardware and software, and improving cybersecurity. WRPS recently completed the design for replacing three waste transfer lines. Double-walled piping is used to move tank waste from double-shell tanks to the evaporator for reduction and to send the resulting slurry back to a tank. Slurry lines installed in 1977 were taken out of service in 2018 after the lines failed periodic pressure testing of the outer encasement piping. While the inner piping that transfers waste has not leaked, the encasement line integrity could not be verified. EM decided to install three new lines, one to transfer tank waste to the evaporator, one to return slurry back to the tank, and a backup line. Other improvements will include a safety system upgrade that will significantly increase the efficiency of equipment testing required prior to an evaporator campaign. -Contributor: Hal McCune |

Team Conducts Vital Five-Year Review of Cleanup Measures in Oak Ridge |

OAK RIDGE, Tenn. – DOE’s Oak Ridge Office of Environmental Management (OREM) and its cleanup contractor UCOR are conducting a critical review of remediation measures in place across the Oak Ridge Reservation virtually as they adapt to challenges from the COVID-19 pandemic.

The five-year, multi-agency review underway is designed to determine if remedies that have been implemented continue to protect human health and the environment. Required by CERCLA — the Comprehensive Environmental Response, Compensation and Liability Act — the review covers the three DOE sites in Oak Ridge — the East Tennessee Technology Park, Oak Ridge National Laboratory, and Y-12 National Security Complex. This is the fifth review since the start of remedial actions in Oak Ridge in the 1990s.

The review included more than 40 interviews held this summer followed by virtual site visits in August and September. Those interviewed included facility managers, engineers, system operators, project managers, subject-matter experts, and site personnel. Regulators, stakeholders, members of the Oak Ridge Site Specific Advisory Board, and others participated in the virtual site visits. Interviews and visits were conducted using online conference systems.

No comments:

Post a Comment